Machinery

Machines brands: Intermac

- Glass Type: Clear, Body Tinted, Hard and Soft Coated Float Glass, Laminated Glass

- Thickness: 3-19 mm

- Edge Deletion: Automatic Edge Deletion

- Max. Dimension: 3210 x 6000 mm

- Min. Dimension: 100 x 100 mm

Machines brands: Intermac

- Maximum machinable sheet size 2500mm x 5000mm

- Minimum machinable sheet size 500mm x 320mm

- Machinable glass thicknesses min 4mm – max 15mm

- Milling and grinding of both notches and openings in the inner part of the glass.

- Glossy and rough grinding

- Boring

Machines brands: Glaston

- Thickness: 3mm – 19mm

- Max. dimesions: 2400mm x 4800mm

- Features: Tempering, Heat Strengthening

- iLook Technology

Machines brands: Hornos Industries Pujol

- Thickness: 3mm – 19mm

- Max. dimesions: 2500mm x 5000mm

- Features: Laminating

Machines brands: Best Makina

- Max. dimesions: 2500mm x 5000mm

- Features: Double & Triple Glazing

Capacity

| Line | Capacity (m2/year) |

|---|---|

| Cutting | 650,000 |

| Double Glazing | 200,000 |

| Edging | 500,000 |

| Tempering | 350,000 |

| Laminating | 150,000 |

Innovative Glass Processing

At GLASS FLEX, we take pride in offering a comprehensive range of glass processing services, backed by our commitment to utilizing cutting-edge technology and advanced machinery. Our state-of-the-art facility is furnished with advanced machinery from esteemed brand names in the glass processing industry, such as GLASTON, BIESSE GROUP, INTERMAC, MOVETRO, BEST MAKINA, HELANTEC, PUJOL, SWF, and many others. With such long-term partnerships, we ensure that our production processes are equipped with the latest innovations and capabilities, enabling us to deliver custom glass products of various shapes, sizes, and thicknesses.

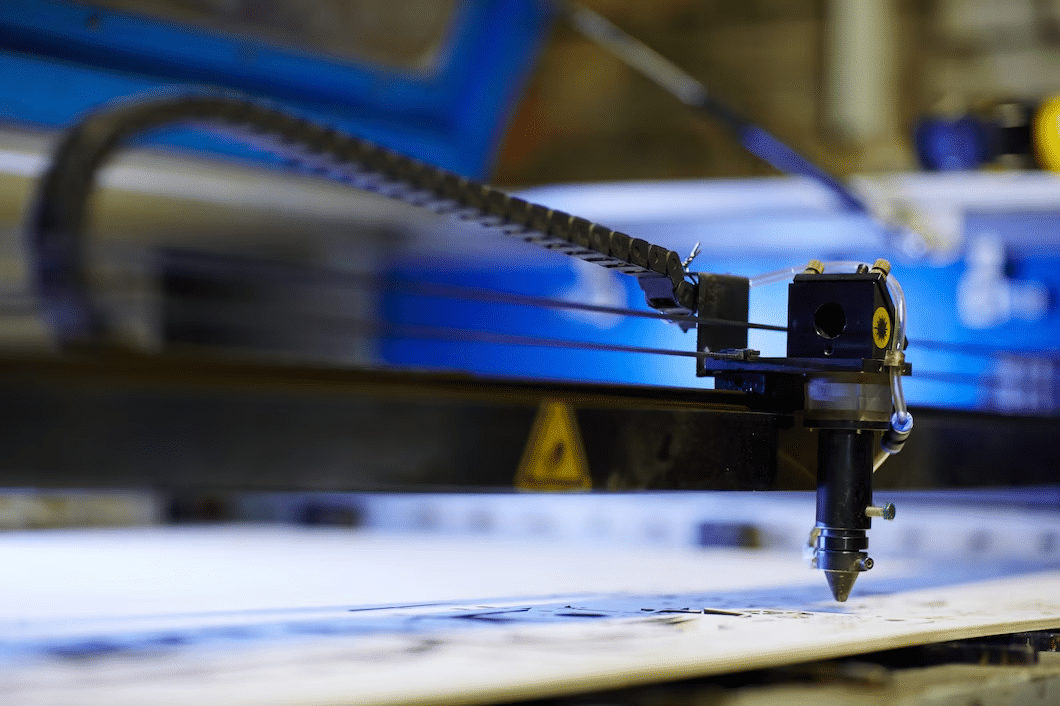

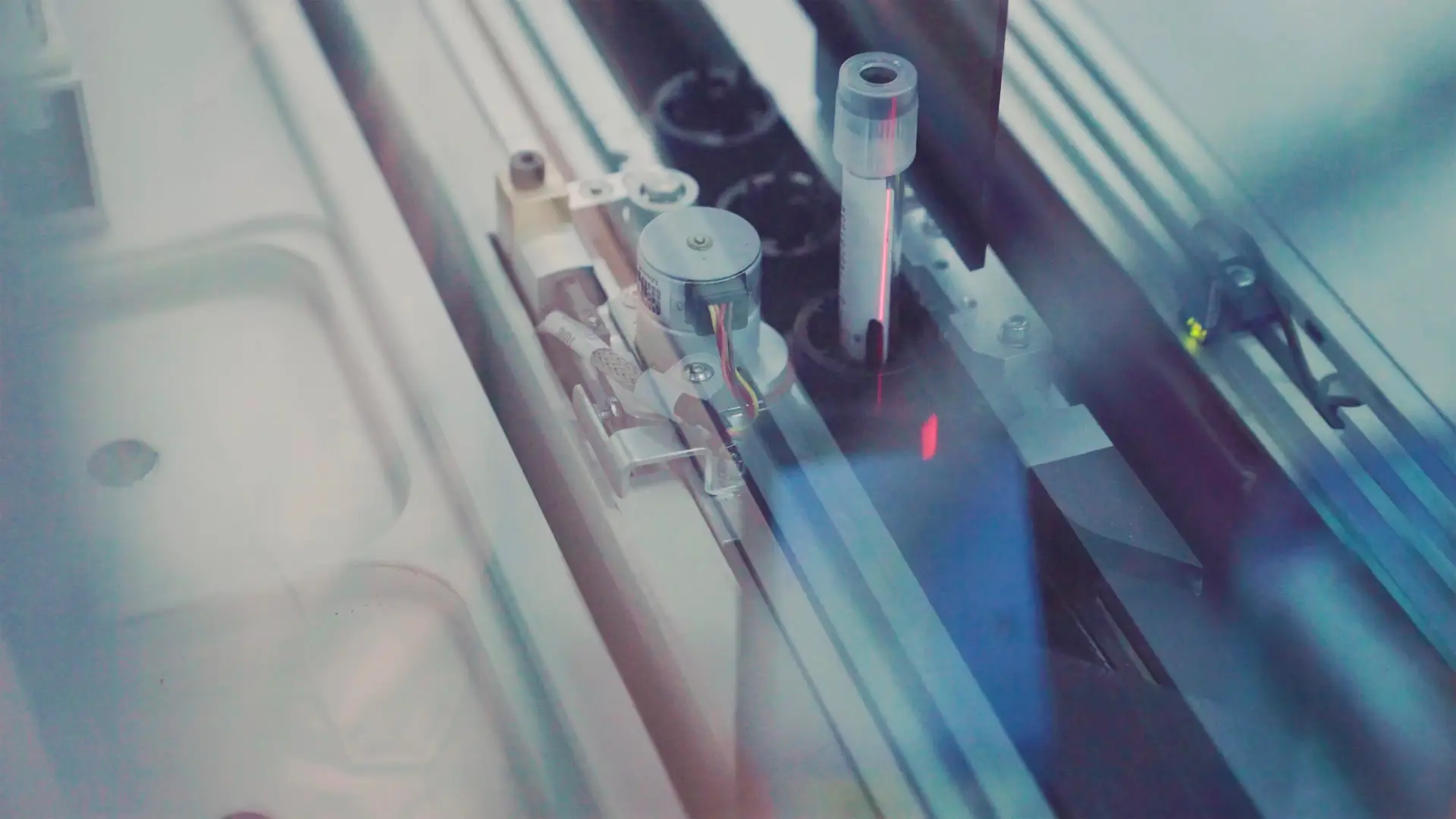

In a modern glass production factory, a wide array of advanced machinery is employed to work with pre-existing glass and transform it into various shapes and forms, including the specialized production of insulating glass units (IGUs). At the heart of the operation lies the glass cutting table, equipped with a computer numerical control (CNC) system, ensuring precise and automated cutting of large glass sheets into desired dimensions and shapes, optimizing material usage and reducing waste. The glass edging machines then come into play, smoothing and polishing the edges of the cut glass, ensuring safety and a refined finish.

To add further functionality to the glass, the factory utilizes a range of tempering and laminating machines. The tempering furnace subjects the glass to intense heat and rapid cooling, significantly increasing its strength and making it more resistant to breakage. Simultaneously, the laminating machine combines multiple layers of glass with interlayer materials, creating laminated safety glass widely used in automotive and architectural applications.

But the factory’s expertise doesn’t stop there. It excels in manufacturing insulating glass units (IGUs) through a dedicated IGU production line. This line consists of specialized machines like the glass cleaning machine, the automatic spacer bar bending machine, and the automatic sealing machine, ensuring that each IGU is airtight and well-bonded for superior thermal insulation. The IGUs produced contribute to sustainable and energy-efficient building designs.

Completing the process are the beveling machines, capable of creating angled and polished edges on glass surfaces, commonly used in mirrors and glass tabletops, adding an extra touch of elegance and functionality to the final products.

With this comprehensive set of advanced machinery and equipment, the glass production factory not only enhances efficiency and accuracy but also offers a diverse range of high-quality glass products, meeting the demands of various industries and satisfying the most discerning customers while contributing to a greener future.

At GLASS FLEX, we pride ourselves on offering a comprehensive range of glass processing services, including cutting, drilling, edging, polishing, tempering, laminating, and more. Our state-of-the-art facility is equipped with advanced machinery that allows us to produce custom glass products of various shapes, sizes, and thicknesses. This includes our specialized production of insulating glass units (IGUs) through a dedicated IGU production line, leveraging a series of specialized machines to ensure airtight and well-bonded units for superior thermal insulation.

As a customer-centric organization, we are committed to investing in the latest technology and equipment, providing our customers with the best possible products and services. Beyond our focus on advanced machinery, we foster a culture of continuous learning and improvement at GLASS FLEX. We believe in empowering our employees to grow and develop their skills, positioning them as leaders in the glass processing industry. This dedication to excellence in both technology and craftsmanship ensures that our glass products meet the most stringent quality standards. Whether it’s cutting, drilling, edging, or beveling, our precision and attention to detail add an extra touch of elegance and functionality to our glass surfaces, commonly used in mirrors and glass tabletops.

With a passion for innovation and an unwavering commitment to customer satisfaction, GLASS FLEX remains at the forefront of the glass processing industry, delivering exceptional products and services that exceed expectations. We take pride in our contribution to sustainable and energy-efficient building designs, offering solutions that benefit both our clients and the environment.